Zippers come in three main types: coil, molded, and metal, each with unique features. Coil zippers use tiny nylon or polyester coils and are flexible and lightweight, perfect for clothing and outdoor gear. Molded zippers have plastic teeth shaped directly onto the tape, offering durability and a sleek look. Metal zippers feature metal teeth, providing strength and a classic appearance. Knowing these differences helps you choose the right zipper for your needs—if you want to learn more, keep exploring each type’s details.

Key Takeaways

- Coil zippers use continuous nylon or polyester coils sewn onto fabric tape, offering flexibility and lightweight durability.

- Molded zippers feature plastic teeth made through high-precision molds, providing uniformity and corrosion resistance.

- Metal zippers are crafted from cast or stamped metal teeth, known for strength and a classic aesthetic.

- Each zipper type varies in application, with coil zippers ideal for casual wear, molded for waterproof needs, and metal for heavy-duty use.

- Manufacturing processes differ, involving coil formation, mold injection, or metal casting, emphasizing quality and durability.

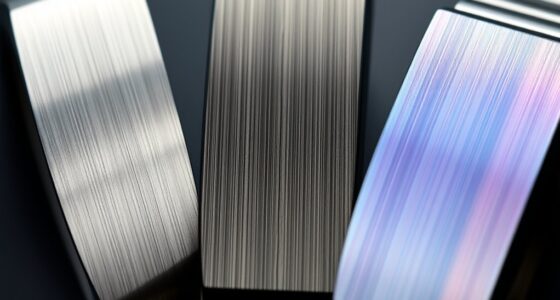

Have you ever wondered how zippers work or what makes them such a reliable fastener? Well, understanding their history and manufacturing process can give you a clearer picture of their ingenuity. The history overview of zippers traces back to the late 19th century, when inventors began experimenting with different types of fastening devices. Early attempts involved hooks, eyes, and clasps, but these proved to be awkward and unreliable. It wasn’t until 1913 that Gideon Sundback, a Swedish-American engineer, developed the modern zipper design. His design featured interlocking teeth that could be reliably opened and closed, revolutionizing fastening technology. Sundback’s innovation laid the groundwork for the zipper’s widespread adoption across clothing, luggage, and various accessories. The manufacturing process of zippers has evolved considerably over the years, becoming more efficient and precise. Today, it involves several key steps: designing the teeth, creating molds or coils, assembling the components, and quality testing. For coil zippers, the process begins with manufacturing tiny coils of nylon or polyester, which are then fed into machines that shape and align them into a continuous chain. These coils are then sewn onto the tape, creating the interlocking mechanism. Molded zippers follow a different route; here, plastic resin is molded into teeth using high-precision molds that produce uniform and durable teeth. Metal zippers, on the other hand, involve casting or stamping metal components, which are then polished and assembled. Modern manufacturing employs automation and computer-controlled machinery to guarantee consistent quality and rapid production. This precision is crucial because it guarantees that each zipper functions smoothly and lasts over time. The entire process emphasizes durability, ease of use, and aesthetic appeal, tailored to different applications. Additionally, advancements in material technology have led to zippers that are more resistant to corrosion and wear, enhancing their longevity. As a user, you might not think about the complexity behind each zipper you use daily, but knowing this background highlights its importance. The development from simple hooks to sophisticated automated manufacturing exemplifies human ingenuity in solving everyday problems. Whether you’re fastening a jacket, closing a bag, or securing a pair of jeans, you’re benefiting from over a century of innovation, engineering, and craftsmanship. The history overview shows how the zipper has become an essential part of modern life, and the manufacturing process underscores the precision required to produce such a small yet indispensable device. Next time you zip up your coat, remember the centuries of development behind that tiny, yet mighty, fastener.

Frequently Asked Questions

What Are the Environmental Impacts of Zipper Manufacturing?

You should know that zipper manufacturing impacts the environment through resource extraction and energy use. By choosing sustainable materials like recycled metals or eco-friendly plastics, you can reduce pollution and waste. Opting for eco-friendly production methods minimizes emissions and harmful chemicals. Your efforts to support brands that prioritize sustainability help lessen environmental harm, making the zipper industry more eco-conscious and aligned with global efforts to protect our planet.

How Do Zippers Withstand Extreme Weather Conditions?

You’ll find zippers designed for extreme weather conditions often feature weather-resistant coatings and corrosion-resistant materials, ensuring they withstand rain, snow, and humidity. During durability testing, these zippers are subjected to harsh conditions to verify their performance over time. Look for zippers with reinforced teeth and sealed sliders, as these enhancements improve weather resistance, ensuring your gear stays secure and functional even in the toughest environments.

Are There Any Hypoallergenic Zipper Options?

Think of allergy-free zippers like a cozy, hypoallergenic blanket—protecting your skin from irritation. Yes, there are hypoallergenic zipper options made from hypoallergenic materials such as nickel-free alloys, plastic, or coated metals. These allergy-free zippers are perfect for sensitive skin, ensuring comfort and safety. You’ll find them in clothing and accessories, providing peace of mind, just like a gentle hug that keeps allergies at bay.

How Long Do Different Zipper Types Typically Last?

You’ll find that metal zippers generally last the longest, often enduring for decades with proper care due to their durability and material longevity. Coil zippers tend to have a shorter lifespan, around 5-10 years, depending on usage, while molded zippers usually last about 3-7 years. Your zipper’s durability depends on the material quality and how often you use or maintain it, so choose wisely based on your needs.

Can Zippers Be Repaired or Recycled Easily?

Yes, zippers can often be repaired with zipper repair kits or professional help, especially for issues like broken sliders or misaligned teeth. Recycling zippers is more challenging but possible; you can separate metal or plastic parts for zipper recycling programs. You should consider repairing first to extend their life, and if they’re too damaged, look for local recycling options to minimize waste.

Conclusion

Now that you know the differences between coil, molded, and metal zippers, you’re better equipped to choose the right one for your project. Did you know that metal zippers have been around since the early 1900s and still hold about 50% of the zipper market today? Whether you prefer durability, flexibility, or style, understanding these options helps you make smarter choices. So go ahead, zip up with confidence and create something amazing!